What is Purity Protocol?

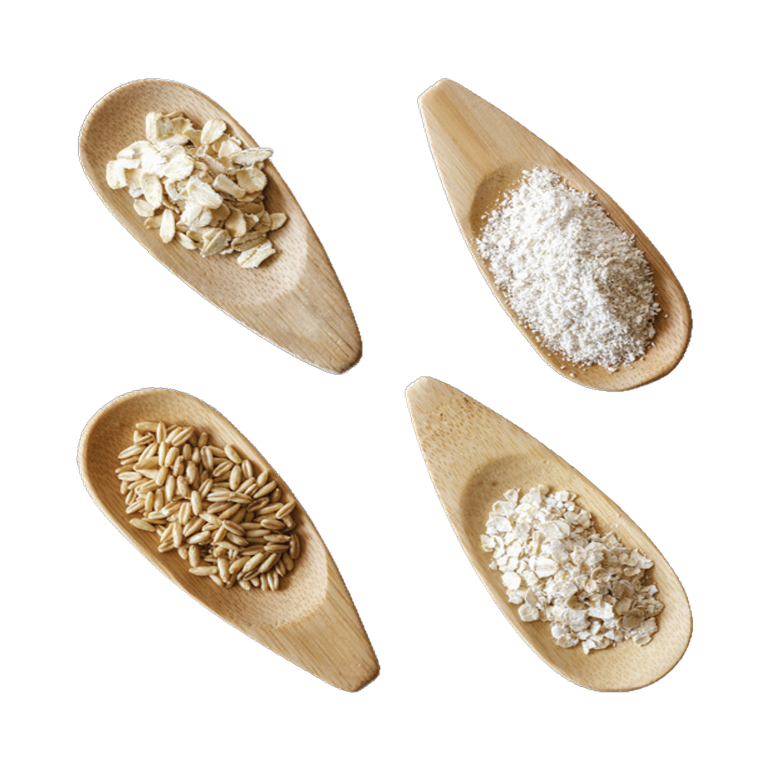

Avena Purity Protocol was established by pedigreed seed growers to grow and process clean gluten-free oats. The goal is for individuals with celiac disease, gluten sensitivities and wheat allergies to be able to source food and beverages that are safe to consume.

Avena is the industry leader in sourcing and processing gluten-free Purity Protocol oats. The Avena Purity Protocol system is a Start Safe, Stay Safe approach, developed over more than a decade, to guarantee certified gluten-free pure oat ingredients.